Holo World! Reflections on a decade in additive manufacturing

It’s sometimes hard to believe that Holo is coming up on its fifth birthday. Time really flies, when you’ve had your heads firmly down, hard at work building a world-class team and technology! Not to mention a little time compression caused by the pandemic.

So, you might be wondering why I'm writing this now. In part, it’s because we’re ready to talk about who we are, what we do and how we do it. But we also hope that this blog will become a resource for you. Whilst Holo itself is 5 years old, the company is a decade in the making. Collectively the folks here have over a century's worth of experience in the additive industry, and we aim to share that knowledge with you across topics ranging from deep dives into engineering applications and discussions on our technology roadmap, to commentary on the industry at large.

Like most blogs, ours aims to be an educational resource — but that’s just for starters. It is also a place where I will speak from a founder’s perspective about who we are, what we’re doing, and (in time) share my thoughts on the industry after being a leader in the space for a decade. In the meantime, let me introduce you to our company, what we stand for and how we came to be. Consider this our “Hello World”. Or rather, as an insufferable lover of puns… “Holo World”!

Customers at our core, leading with technology

We founded Holo to lower the barriers of adoption in additive manufacturing (AM). That’s quite possibly one of the most overused phrases in AM, and one we dare not say out-loud beyond our doors. But internally, it has almost fanatically driven us to truly understand what challenges our customers face. In fact, it has led us to one of our core principles at Holo - something we call customer intimacy. And it’s from that shared partnership and understanding with our customers that we realized we had to build the company on a counterintuitive business model: we would be a 3D printing company that doesn’t sell 3D printers.

We didn’t start out that brazen. Prior to Holo, our team built the Ember 3D printer at Autodesk - and we sold printers just like everyone else. However, we realized that if we kept doing that, not only would our customers have to fork out upfront machine costs, but they would be burdened with developing a business case — and applications that would bring them value — before they’d even had experience with the technology. And after that leap of faith, once they brought a printer in-house, they still had to develop the process knowledge, design understanding and expertise of running AM hardware. To make matters worse, to access the incremental technology improvements that accompany new hardware releases every 2-4 years, customers would have to pay for them and go through that cycle again and again. Talk about barriers!

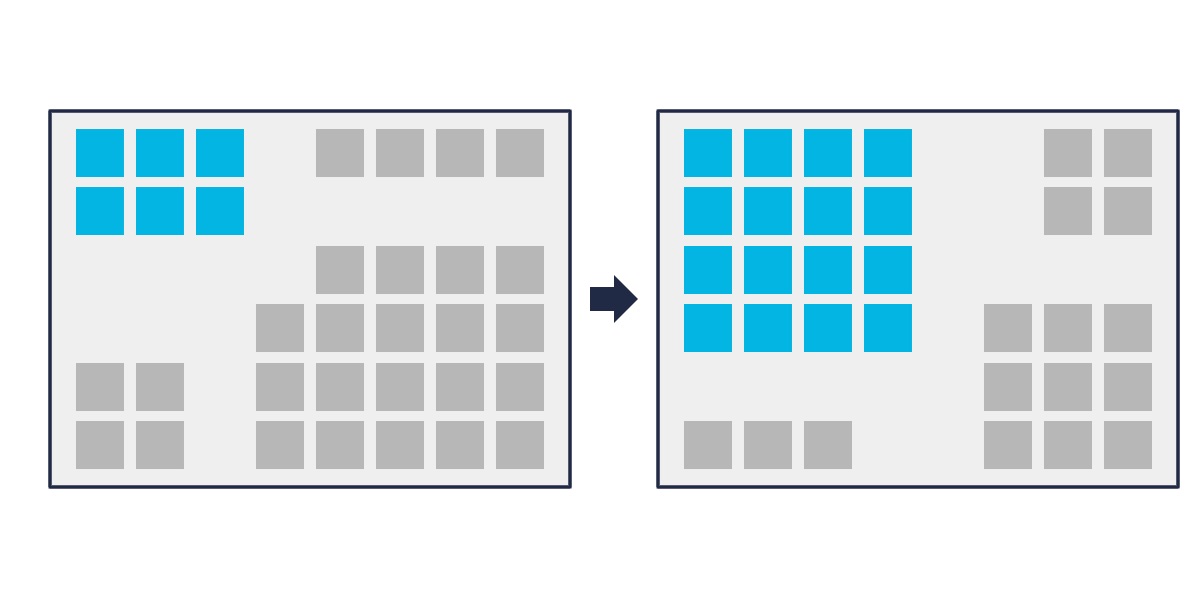

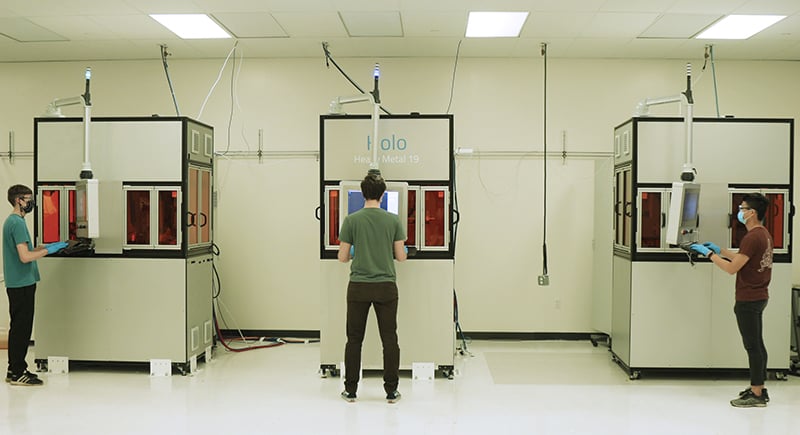

Developing and running our printing processes and equipment internally allows us to implement upgrades to our printer fleet (a few of which pictured here) extremely rapidly.

Spinning out from Autodesk and becoming Holo five years ago allowed us the freedom to take Holo on a non-traditional path for a 3D printing OEM: offering parts manufacturing as a service. Ultimately this provides our customers with frictionless access to our technology, while allowing us to focus on keeping the pace of technology development and offering those improvements on an almost daily basis.

Focusing on the boring stuff

At Holo, we’re proud to be able to say that our customers get what they want — hassle-free precision parts, fast. We provide an easy approach to sourcing metal parts with intricate features and exacting tolerances, with a seamless pathway from prototyping to volume production — or as a powerful bridge to mass manufacturing technologies. As a team, we believe that great products and services are no accident, but the result of an intense, relentless focus on the small details, the second- and third-order engineering considerations, and impactful end-to-end system performance optimizations. The reason we’re confident in our technology is that we are completely vertically integrated. Our company — and tech stack — was built from the ground up by the smartest hardware, materials, software and design engineers in the industry, which gives us complete control over the process and allows us to do what we can do best - obsessing over, and refusing to be satisfied with the boring stuff: dimensional tolerances, repeatability, throughput and cost.

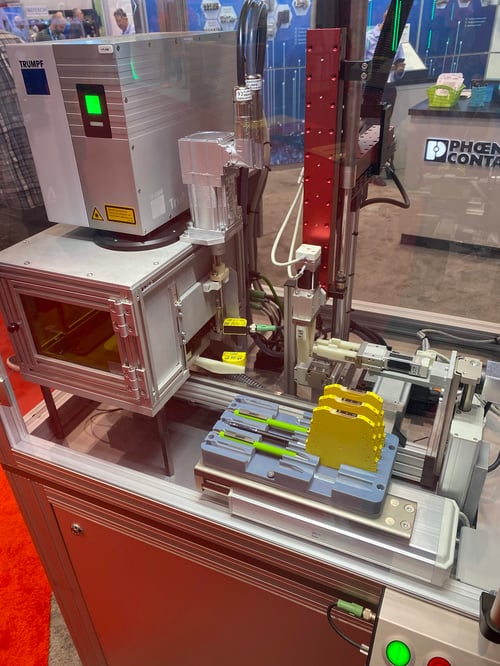

If you look at traditional manufacturing technologies, none of this is new — CNC machining and turning, the entire family of EDM technologies, injection molding, MIM, and more, have all hard-earned their respective places in the manufacturing world through rigorous development, real-world capability trials, and vendors seeking ongoing feedback from an uncompromising user base. OEMs of traditional manufacturing equipment acknowledge how critical their products are to the livelihood of their customers, by taking seriously their responsibility to deliver the performance they promise, and continuing to develop tools that make their customers’ operations more reliable and predictable — something we saw on full display at IMTS 2022 this year.

Precision, reliability, and consistency have all been long embraced and exemplified as critical performance characteristics by traditional manufacturing technology companies. This automated laser marking cell seen at IMTS 2022 is a great example of this. Additive manufacturing as an industry isn't quite there yet, although momentum is growing.

The 3D printing industry as a whole, is still by and large catching up in this area of quantifiably consistent performance — what we at Holo have been focused on since our founding five years ago. Additive manufacturing has gone through so many marketing hype cycles, in part because the focus has largely been on endless lofty goals and promises of what AM can offer in the future, rather than sweating the fine details of what end-users need today: to be able to trust and rely on the technology in their everyday work. It’s why so many additive press releases tout wonder features that never come to fruition, and why so many spec sheets have asterisks and exceptions. When 3D printing companies over-promise and under-deliver, not only do people lose trust in those companies, but they lose trust in additive as a whole.

Engineers are some of the most discerning and (rightly) skeptical individuals — and as engineers ourselves, we’re speaking from experience. Manufacturing specs are black and white. Things are either in spec or out of spec — they have the mechanical qualifications or they don't — and the cost of out-of-spec parts (or a new capital expenditure that didn’t deliver what it promised) quickly eats up profit margins that are already thin to begin with. Engineers are inherently conservative for this reason. Our team at Holo is highly focused on meeting and exceeding these rigorous engineering requirements. And by offering our customers a parts service, rather than selling printers, they have an extremely low-risk avenue to test out our capabilities, without ever needing an upfront capital investment.

Where to next?

For the past five years, we’ve had our heads down: no splashy marketing, no over-promising or under-delivering — and we’re going to keep it up. We’ve been busy solving real problems for our customers, and ensuring our technology truly does everything we say it will, because we’ve brought that same skeptical, ‘disbelieve it until we can prove it’ engineering mindset to our own work.

Our ‘why’ in the big picture has crystalized as well: recent years have brought us the COVID-19 pandemic, war in Europe, and other challenges to the globalized supply chain that have led to a collective realization that the US (and other countries) needs to restore domestic manufacturing excellence. We know that we can be one piece of the greater effort towards providing solutions.

While it’s time for us to talk about ourselves more publicly (you can’t help solve engineering challenges if engineers don’t know you exist), I hope Holo and the articles in this blog will contribute to wider industry discussions. We’re going to talk about the boring stuff (although we promise to keep it entertaining!). You can expect to read the things that engineers like ourselves actually care about — tolerances, repeatability studies, and detailed examples of successful applications to name a few. Our focus remains on continuing to develop tech that produces parts exactly as you expect, in the materials you want, every single time.

And finally, if you have a project that you’re having trouble sourcing intricate metal parts for, reach out to our engineering team to set up some time to chat and see if we can help. Or if you’re just curious to keep up with what’s new, sign up for our newsletter.

-Arian

By

By