Applications of PureForm™ metal additive manufacturing

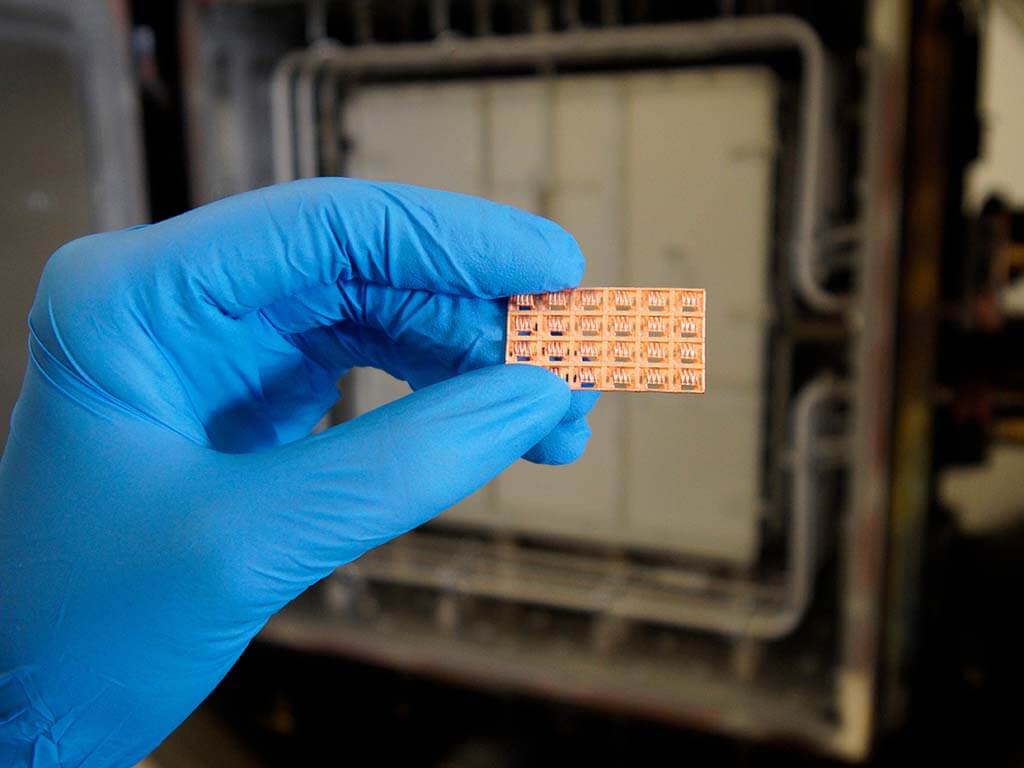

Parts created with Holo's PureForm technology are accelerating the engineering development and manufacturing of advanced products across a diverse range of industries from electric aircraft propulsion to wearable AR/VR equipment.

What do they all have in common? Read on to find out.

Too complex for traditional manufacturing...

Part complexity unites most impactful use cases of our PureFrom metal AM technology – specifically geometries that are

Rapid iteration, incredible intricacy

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

- Bullets are great

- For spelling out benefits and

- Turning visitors into leads.

Mismatched capabilities and unit economics

Something Powerful

Tell The Reader More

The headline and subheader tells us what you're offering, and the form header closes the deal. Over here you can explain why your offer is so great it's worth filling out a form for.

Remember:

- Bullets are great

- For spelling out benefits and

- Turning visitors into leads.

Industries served

Tabs are an effective way to organize information on a website page when there is a large amount of content that needs to be separated into distinct categories. Label your tabs with one or two words that define each category of information.

When styling your tabs, highlight the selected tab by giving it a color that differs from your unselected tabs, so that it's easy for your visitors to navigate.

Tabs are an effective way to organize information on a website page when there is a large amount of content that needs to be separated into distinct categories. Label your tabs with one or two words that define each category of information.

When styling your tabs, highlight the selected tab by giving it a color that differs from your unselected tabs, so that it's easy for your visitors to navigate.

Tabs are an effective way to organize information on a website page when there is a large amount of content that needs to be separated into distinct categories. Label your tabs with one or two words that define each category of information.

When styling your tabs, highlight the selected tab by giving it a color that differs from your unselected tabs, so that it's easy for your visitors to navigate.

Tabs are an effective way to organize information on a website page when there is a large amount of content that needs to be separated into distinct categories. Label your tabs with one or two words that define each category of information.

When styling your tabs, highlight the selected tab by giving it a color that differs from your unselected tabs, so that it's easy for your visitors to navigate.

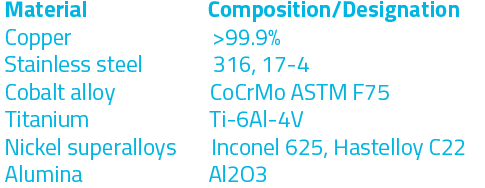

A material advantage

If it can be powderized and sintered, Holo can print it. Holo’s binder technology is compatible with a wide spectrum of materials including metals, complex alloys and ceramics. As a slurry, it requires no costly, time consuming powder handling. Material efficiency is very high, virtually all material is incorporated in printed parts.

Materials in production and development

Technology advantages

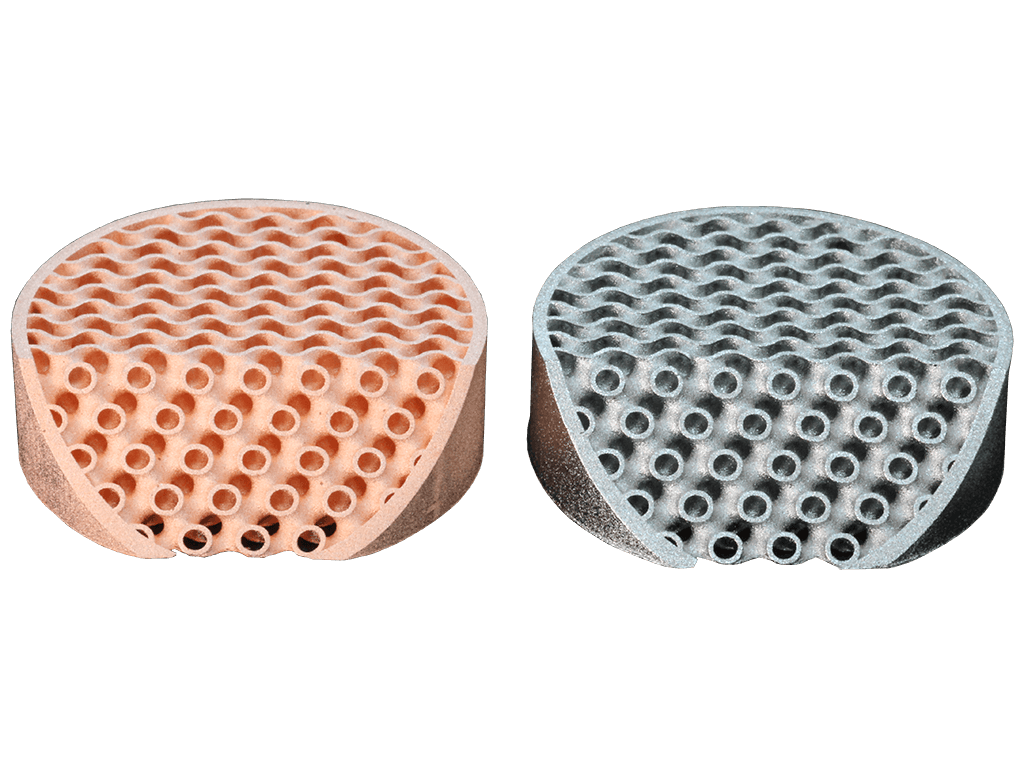

99.9% material purity

Holo’s proprietary polymer is engineered to vaporize during part sintering. The result is highly pure parts with properties approaching bulk material. PureForm™ material purity exceeds that of other additive approaches.

As an example, Holo’s additive manufactured PureForm copper is 99.9% pure, achieving thermal and electrical conductivities comparable to bulk copper.

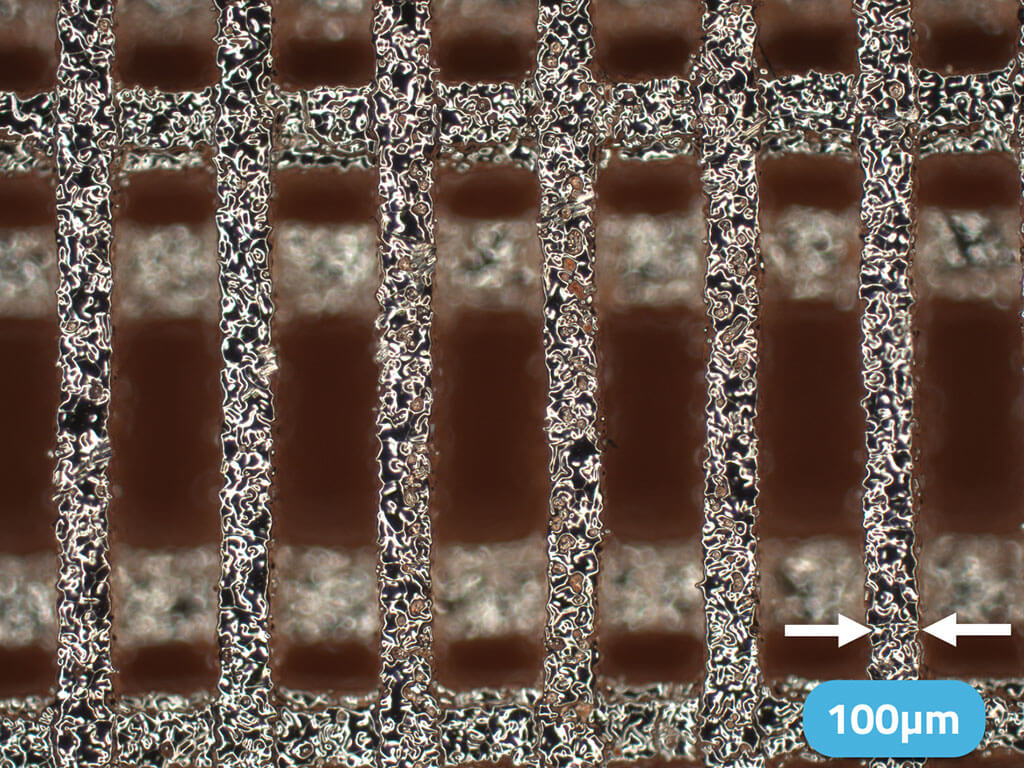

Finest resolution

With features down to 50 microns with 100 micron walls, the PureForm™ platform prints parts previously only possible with expensive Swiss CNC machining.

Unparalleled AM resolution allows complex internal geometries in spaces where tools won’t fit, delivers thinner walls than MIM, directly prints functional threads and provides superior gas and liquid flow characteristics with intricate, powder-free internal channels.

Strong technology foundation

Holo has expertise in printer development, materials science, product design and algorithm development. The company has 22 patents and 34 patents pending covering a wide variety of subjects including additive manufacturing, design for additive, PureForm printer design, PureForm materials and thermal design.

Review an application

If you have a project that you'd like us to evaluate, let's chat! We'll request some brief technical info on the components you're seeking to have manufactured and then an expert from our team will set up a time to discuss.